BENEFITS OF SINGLE-USE SYSTEMS

Optimize Product Recovery and Scalability

Since 2009, CARR Biosystems has been providing single-use separation systems to biopharma companies seeking low-shear separation, high-recovery performance, and fast processing time. Avoid the expense and waste of CIP/SIP stainless steel centrifuges and step up to the scalable, industry-leading, UniFuge platform.

More Data in Less Time

Get more data in less time while lowering costs. Our smallest scale UniFuge technology – UFMicro – requires minimal cell culture volume and technician time.

Optimize your process performance when developing process CTQs with low-shear separation and remarkably high processing speed.

Scale-up Seamlessly with UniFuge

De-risk Process Scaling: Establish easily transferable CTQs as you pass clinical milestones.

Optimize product quality via tunable process settings (flow, force).

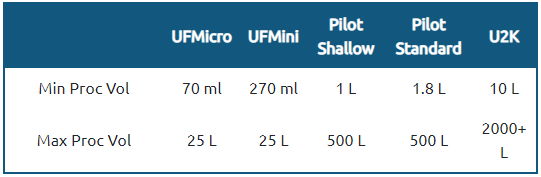

Processing volumes to support you from process development to commercial manufacturing:

Unsurpassed Performance

- Optimize separation performance with best-in-class low-shear separation ensuring:

- High cell viability for cell therapy and cellular agriculture applications

- Isolation of antibodies from cell culture supernatant

- Reduction of BSA levels well below the required minimum

- Achieve high processing speeds without sacrificing the separation efficiency needed for demanding applications

With a small footprint, UniFuge systems are easy to operate, simplify training and require fewer staff than traditional centrifuges.

- 100% closed system

- Low shear

- Clear center

- Reduce filtration needs by 85%

- Set up and change over within 15 min

- Cell viability up to 98%

- Yield up to 98%

- Confidently scale up to the U2k® or scale down to the UFMini®

- Variable speed up to 4,000 x g

- Reduce HCP and other contaminants

- GMP-compliant data trail 21cfrPart11

- Extractables data available

- SAL level 10-6

Advantages of Single-Use Centrifuges

Easy-to-use, reliable equipment that delivers high product recovery.

Performance

Our proven low-shear technology boasts up to 98% yield and 98% or higher typical cell viability.

Scalability

Our equipment can be used from development to commercial licensure and across different reactor volumes.

Ease of Use

Our machines are rapid to install and simple to operate.

Small Footprint

Our single-use centrifuges have a small footprint.

THE UNIFUGE FAMILY

The scalable UniFuge family of centrifuges has a variable g-force up to 4,000 x g. They employ gamma-irradiated sterile single-use modules, reducing the risk of contamination.

UFMini®

The UFMini boasts a small footprint, with either 70 mL or 300 mL bowl and a flow rate of 29-1,000 mL/min.

UniFuge® Pilot

The UniFuge Pilot is a mid-sized centrifuge with a 1.8 L bowl and a flow rate of 1-4 L/min.

U2k®

The U2k is the largest member of UniFuge family, with a 9 L bowl and a flow rate up to 5-20 L/min.

Our reliable and robust stainless steel equipment addresses even the most challenging separations. Leading biopharmaceutical companies around the world rely on our machines to manufacture their licensed products. Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems can be used during product or batch changes to prevent contamination.

Powerfuge Family

- Designed for bacteria, fungi, proteins and sub-micron particles

- Proven for the production of plasmid DNA, vaccines, plasma protein, cellular agriculture and specialty chemicals

- G-forces up to 20,000 x g, the highest g force in the market

- Bowl volumes from 1.1 L to 36 L

- Flow rate from 250 ml/min to 1700 L/hr

- Solid-bowl centrifuges

- Automatic solid discharge

- SIP/CIP capabilities

- Hazardous duty option available

Viafuge Family

- Designed for mammalian, insect and plant cells

- Typical cell viability of 98% or higher

- Yield up to 98%

- G-forces up to 10,000 x g

- Bowl volumes from 1.4 L to 16.7 L

- Flow rate 2,400 L/hr

- Solid-bowl centrifuges

- Automatic centrate discharge

- SIP/CIP capabilities

Advantages of Stainless Steel Centrifuges

Our long history and deep expertise with pioneering separation technology allows us to deliver top-performing solutions through a reliable supply chain.

Performance

Our reliable and robust centrifuges address even the most challenging separations.

Scalability

Our equipment accommodates small process development volumes to very large commercial needs, allowing for seamless scale-up and scale-down.

Versatility

Our stainless steel centrifuges are designed to serve a variety of markets.

The Powerfuge® Family

Powerfuge centrifuges are well suited for separation of bacteria, fungi, proteins, and sub-micron particles. At the end of a run, compressed solids can be removed with minimal time and effort.

Powerfuge Pilot

The Powerfuge Pilot is a high-power batch liquid/solid separation system with a 1.1 L bowl and flow rate of up to 60L/hr for batches up to 100 L.

Powerfuge P6

The Powerfuge P6 provides continuous-flow two-phase separation of solids and liquids with a 1 L bowl and flow rates up to 60 L/hr for batches up to 100 L.

Powerfuge P12

The Powerfuge P12 System provides continuous flow two-phase separation of solids and liquids with a 8 L bowl and flow rates up to 500 L/hr for batches up to 500 L.

Powerfuge P18

Boasting the highest capacity in the scalable Powerfuge family, with a 36 L bowl, the P18 System has a flow rate up to 1,700 L/hr for batches of up to 2,000 L.

The Viafuge® Family

The Viafuge centrifuges are low-shear stainless steel systems designed for separation of mammalian, insect and plant cells with typical cell viability of 98% or higher.

Viafuge ® Pilot

The smallest member of the scalable Viafuge® family, the Viafuge® Pilot has a 1.4 L bowl and can be optimized for specific applications with a flow rate up to 2,400 L/hr for batches up to 500 L.

Viafuge ® V12

The Viafuge® V12 comes with a 9.6 or 16.7 L bowl, a variable speed drive, and a flow rate up to 2,400 L/hr for batches up to 2,000 L.

中文 (台灣)

中文 (台灣)